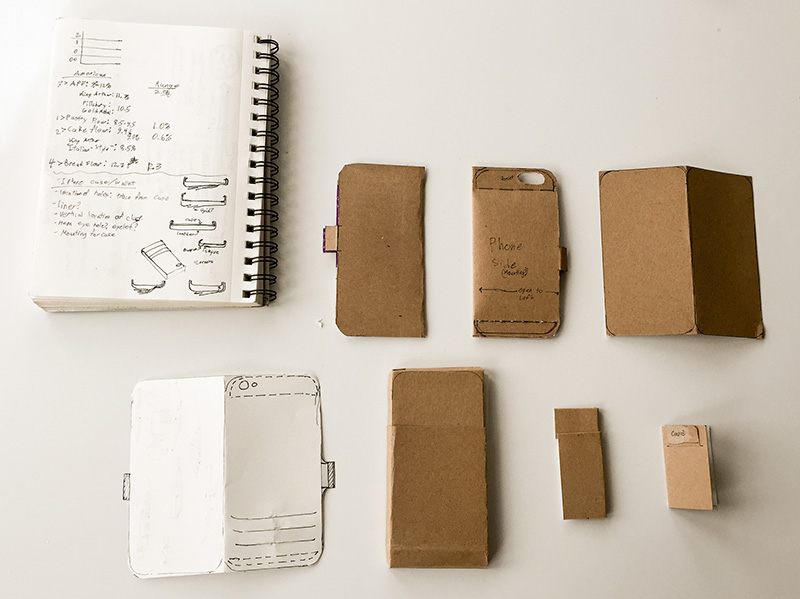

I haven't forgotten my intention to build my own wallet-phone case, as my current case is on it's last leg. I've actually researched a fair amount of leather working technique and scoped out possible sources of leather and tools (probably just order online.) From my research it became clear that I needed a clear understanding of how this was going to come together. I needed to know exactly what I'd be doing with the leather when I eventually got it, and in what order, so this past weekend, I sat down and started working out prototypes.

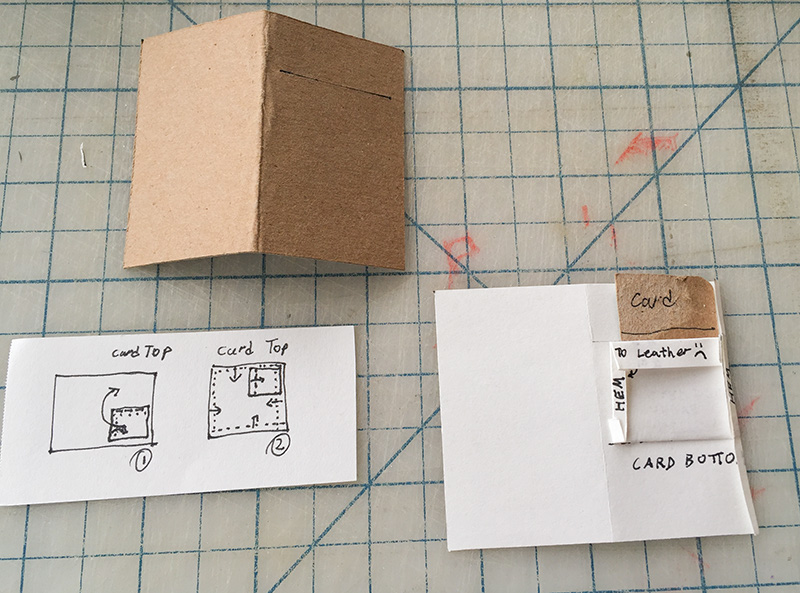

Rather than using actual leather, at this phase, I've decided paper will suffice. I flattened out an old cereal box to use chipboard to simulate a thicker leather, and tore some pages of white paper from my sketch book to act as fabric (for liner and pockets and such.) I started with a paper template which was basically a tracing of the phone.

I'd had this design in mind from the start: the leather attaches to the back of a plastic phone case, and folds in half at the long edge and stitched on the top and bottom to create a pocket (closed by a clasp.) There would be slits in the back fold of leather for important cards to be accessed. The leather stitch locations are most likely the last steps though. After cutting this out in chipboard, I simulated leather stitching with staples. Before I could close this pocket, I needed to figure out how to sew in the liners of both the card pockets and cash pocket. This was a lot more difficult that I initially anticipated, and I ended up working through a few liner specific prototypes to isolate that problem.

I'm trying to keep things neat, thin, and durable. I broke out some of my old wallets and picked and pulled at them to figure out how they were made (as well as what ways they failed. I don't know much about soft-goods, but I'm speculating that for durability it's not ideal for the cards to butt directly into a seam. Rather, the ideal pocket would cradle each card with the fabric, though this would add to thickness. I also wanted to keep the hems of both fabric and leather neatly bundled to avoid any chance of fraying, the folding over of liner and leather compound to make the order of operations somewhat confusing. As I tried to simulate a lining process with paper and glue, it became clear that this was to be a difficult if not nearly impossible set of constraints for me to meet.

I was either wearing down or getting creative when I decided to explore a different design all together, which I mostly just sketched out in concept: What if there was no folded over leather, but simply a pocket formed between the leather and the phone case? This would simplify the lining process a bit, and would help reduce the thickness. It introduces a new problem set though of figuring out the best ways to join plastic and leather. Guess that means more research.

greeat works