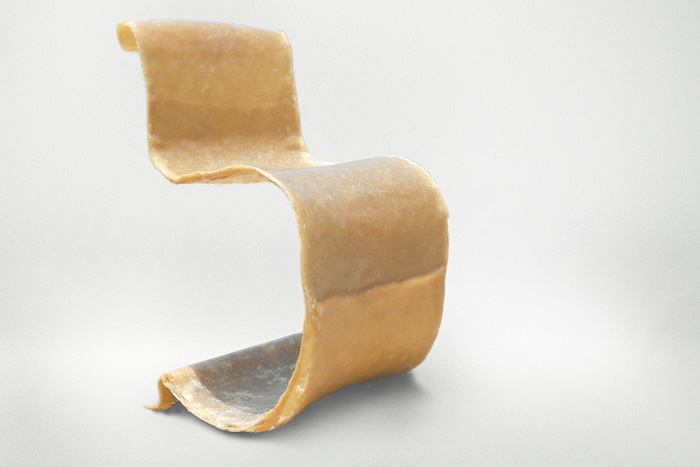

As part of a materials research project, a classmate and I built a chair out of fiberglass sheets laminated together with resin. While researching the typical application of this composite material, we found that it is often used as a finish treatment supported by an internal structure. The 2 exceptions to this were found in boat construction, where fiberglass is often used the primary hull material, and surfboard assemblies, where an internal piece of foam creates thickness around which fiberglass adds rigidity. We took inspiration from these systems to create an S-shaped chair out of fiberglass sheets, resin, and foam.

To minimize foam use, the interior of the mold was built around an armature of plywood with 2" thick CNC milled foam. The surface was doubly curved to increase rigidity. We coated the foam mold with duct tape to help release the cured resin, smooth out the finish surface, and to seal the foam from the resin, which it would otherwise corrode.

![Exploded-[Converted] Exploded-[Converted]](https://i0.wp.com/www.nikinnaird.com/wp-content/uploads/2015/08/Exploded-Converted-e1439011262468.png?w=405&h=479&ssl=1)

The final chair was about 14 layers of fiberglass mat, with a significant amount of resin. The embed foam piece provided the necessary thickness for the chair to be structurally sound. The mold was smooth enough to allow a clean release. Rather than painting the chair, we decided to leave exposed the raw color of the resin.