To me, freelance work is sort of like bartending. There’s not really a clear-cut path to doing it, and everyone has a different story of how they got started. Maybe that “blaze your own trail” (read: “make it up as you go”) attitude was part of the appeal for me.

My most recent job was actually a continuation of some work I had done in the past for a particular coffee roasting company here in the Bay Area. At first, I advertised as a 3D modeler with knowledge in prototyping, rendering, CAD drafting and fabrication. I wasn’t sure what kind of work to expect, so I was casting a wide net. When the company contacted me, they needed help prototyping a bottle for a new product they were launching. Apparently, custom molds for bottles can get fairly expensive (around 5k per mold I’m told,) so they had to make sure the design was exactly right. They wanted to try 3D printing, but didn’t know where to start, and didn’t have any modeling software. I was delighted to help out. Bottles are straightforward to model, and I know what to expect from 3D printing, so I offered to do the models and source a good 3D printer for the job.

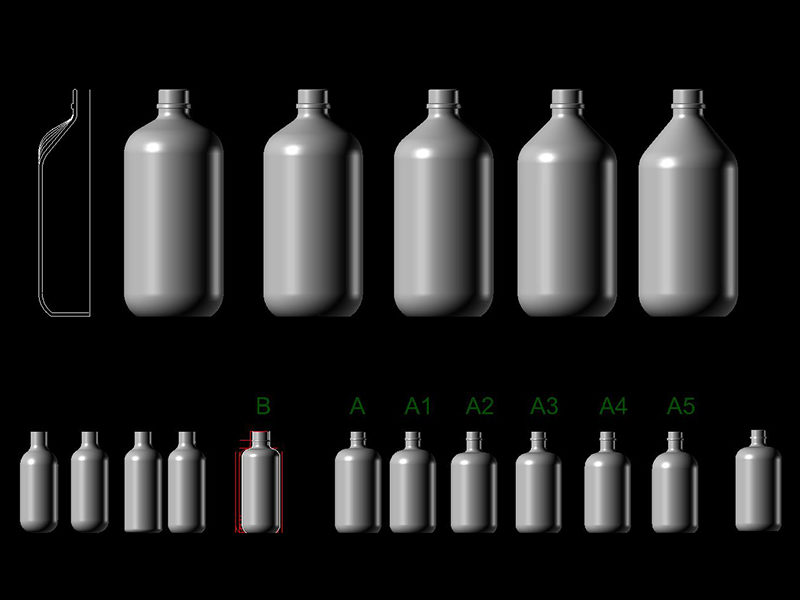

The catch was that they were on a VERY tight deadline (one week.) When estimating time frames, I do my best to manage expectations, but at the same time I really wanted to make it happen for them. It was probably pure luck that I was able to find a local printer with reasonable prices AND work through a few iterations of bottle forms until the client was happy with them. Here’s the full evolution the design took as I worked with them.

It took a few late nights, but a week after they sent me their sketches, I was able to hand them a 3D print (two in fact.) This was also when I learned how to change the index of refraction and made some renderings for them as well. Check out my part 1 post!

While that first job wasn’t perfect, I must have done well enough. They have come back to me twice now with new projects.

For the first project, they requested 3D prints, and I offered the renderings as an extra service since I would have the model built anyway. This time however, they asked only for renderings. As helpful as 3D prints are, they aren’t always necessary, so I’m glad I could save them money by simplifying the decision making process.

Here are the new bottles:

I have a better grasp of my new rendering trick. In addition to changing the material’s index of refraction, I began to understand how the software maps textures onto surfaces and used that to apply labels to the bottles. The labels provide an important sense of scale, which is crucial for these bottles, which were meant to hold a smaller amount than the original product. I also did volume checks to verify exactly where the 14 oz line would be and added some bright orange juice to the mix. Delicious!

In the end, the company did end up ordering a final 3D print, but only of the shorter bottle instead of all three. I felt good that renderings helped them pick a design.